Total Valeting new and used car valeters are trained in the preparation and application of paint protection, ceramic coatings and upholstery protection

After the vehicle has been cleaned to remove surface grime, dirt and major debris, the bodywork is left with a cleanish canvass. We then move onto breaking up hard contaminates that are deep in the microscopic peaks and valleys in the paints top coat with a clay bar and lubrication fluid.

Any swirl marks, light scratches or faded paint will need paint correction for the ultimate finish. The final step in the preparation of the application is to wipe the entire vehicle surface with an Isopropyl Alcohol (IPA) solution. This removes oils, lubricants, waxes, polishes and microscopic particles left on the body.

Once the preparation work is complete we recommend the vehicle to be left inside away from direct sunlight giving the opportunity for the body surface temperature to reduce.

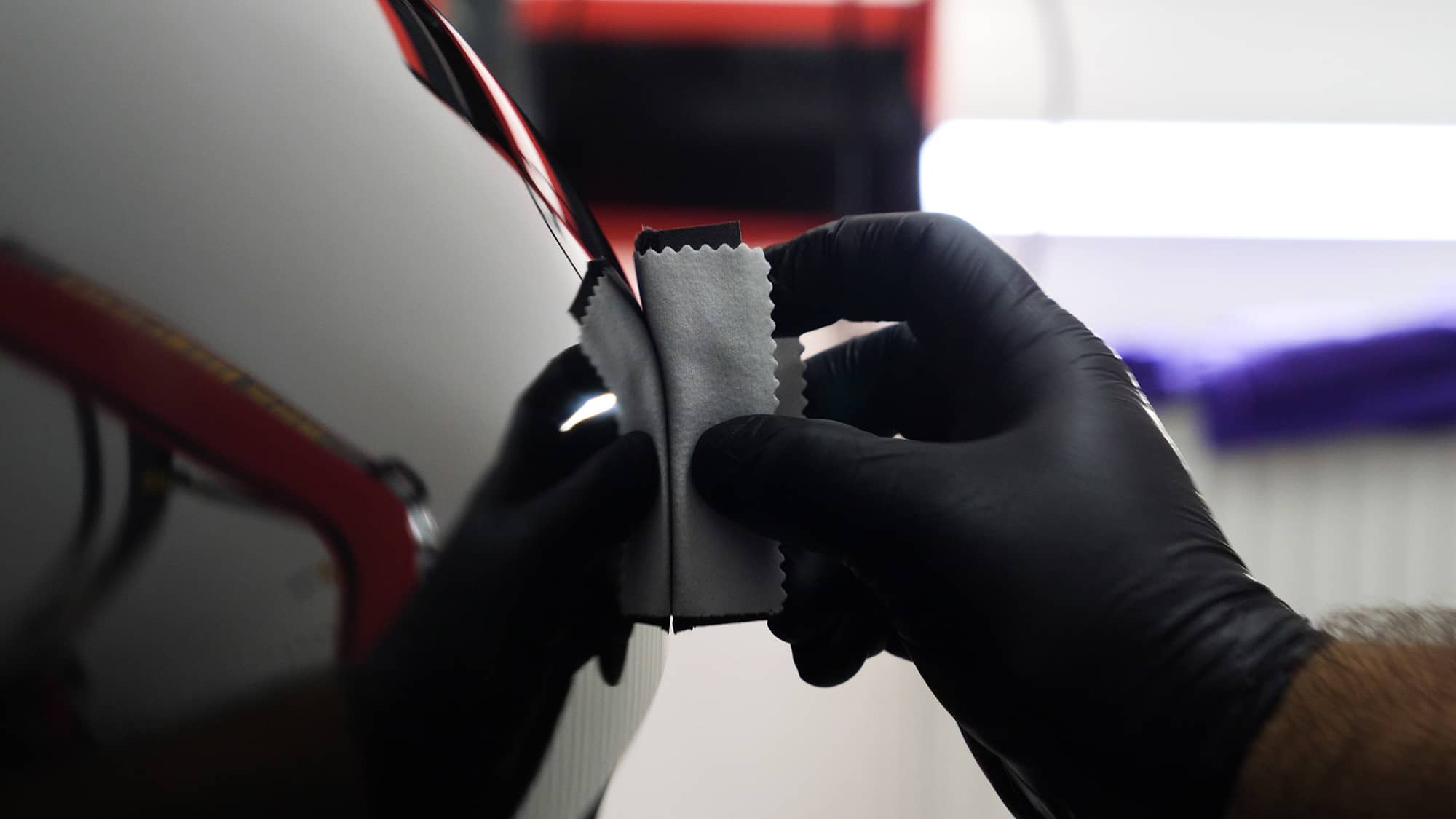

The ceramic coat is applied evenly across the paintwork (one panel at a time), the initial cure takes between one to five minutes. The final step is to buff the coated area (panel by panel) with a microfibre cloth to remove the cloudy surface. Once this stage is complete we recommend leaving the vehicle for up to two hours.

Every ceramic coating is unique and we recommend following the manufacturer's recommendations for the curing process. The initial bond cure takes only a few minutes, however, we recommend the car sit for 24 hours to reduce exposure to water.

The average Isopropyl Alcohol preparation and paint protection application will take one hour from start to finish.